Microcoulometric methode KF analyzer

As a leader in Microcoulometric Karl Fischer analyzer manufacturer until more than 45 years, Nittoseiko Analytec Inc. ( Prevously Mitsubishi Analytech Co) is able to propose you the most wide choice of different configuration, as the small portable system KF analyser

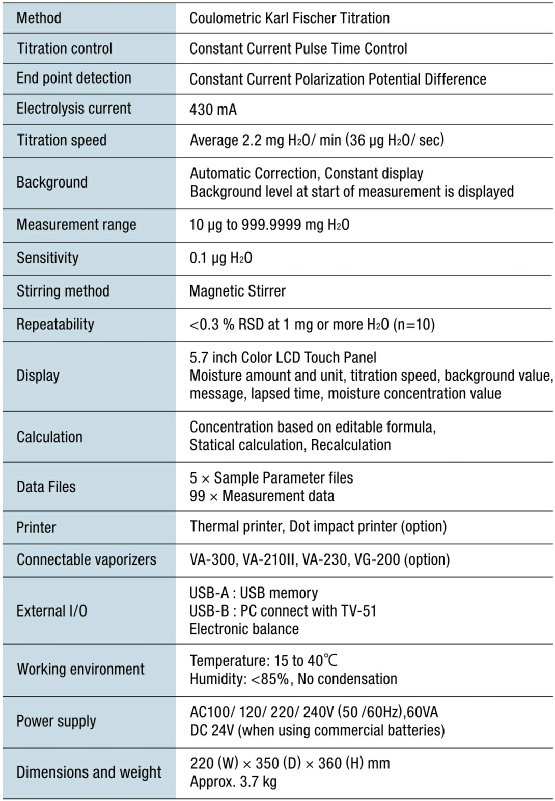

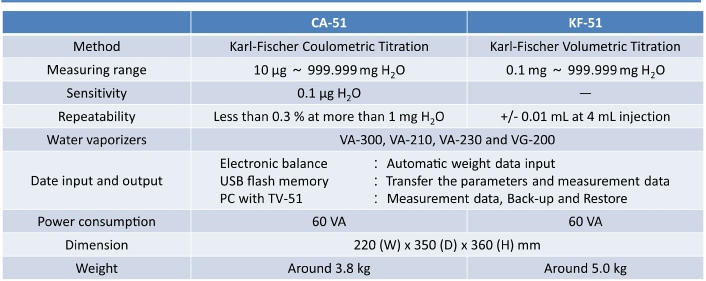

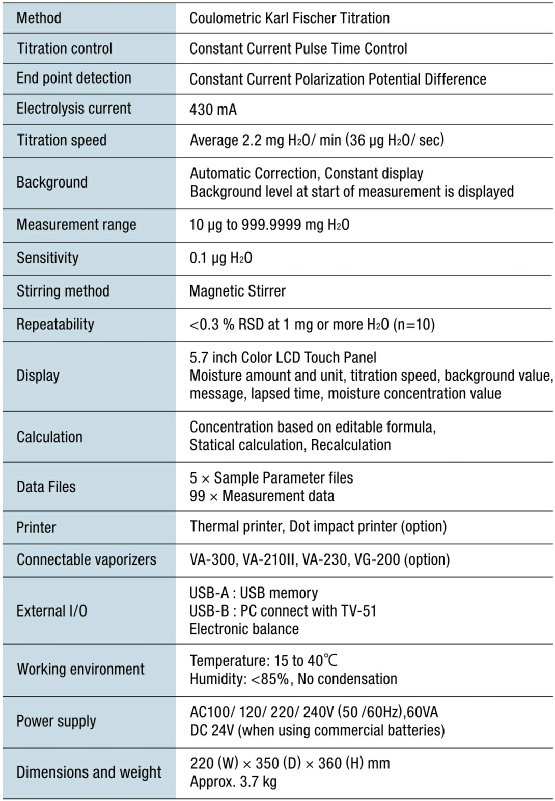

CA -51 Microcoulometric method

For on site analysis or in your laboratory

Less reagents handling and cost due to microcoulometric titration

Highest sensitivity and reproducibility

Touch screen control and USB interface

Range: 10 ug to 1000 mg H2O

Sensitivity: 0,1 ug H2O

Background : Automatic correction

Can be configured with battery (option)

Example of Application

Moisture in transformer oil

Moisture analysis on production site

QC control

Routine analysis

High sensitivity analysis

Fit to all small laboratories or take your analytical instrument with you !

We propose you a set of KF reagents from the highest quality:

AQUAMICRON Reagents: Provided in small quantity, 100ml up to 500 ml bottles for anolyte

AQUAMICRON Reagents : In small 5ml Ampoules for catholyte

Analytical standard are also available in ampoules of 5 ml

Choose the highest quality for your KF reagents

If you need more detail about the reagents or KF applications please contact us by mail, we will send you more information’s and actual prices by return either in electronic form (pdf files ) or by normal mail

KF Reagents and standards

Download info

Download info

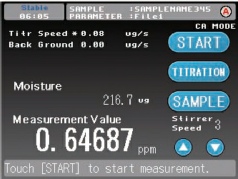

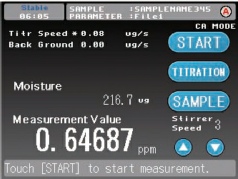

A large touch screen display is on the upper front of the instrument giving a clear information about the status of the analysis.

All information's are in on screen

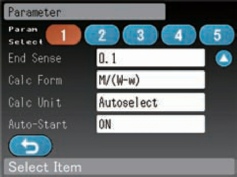

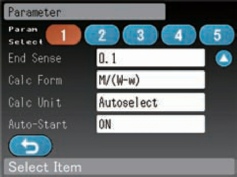

Information's are given to guide the user through the instrument setup

Only follow the displayed info and at the end start the titration.

Fill up the coulometric titration cell, start instrument, the instrument check the blank background, titrate by microcoulometry automatically this blank down and check for stable base line.

A soon the value is stable, a message inviting you to inject the sample in the cell is displayed, the titration starts automatically until the end, and finally the result is displayed and registered in the internal memory file.

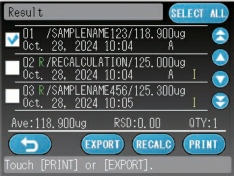

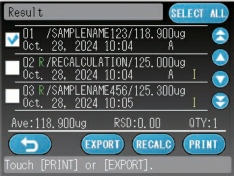

The previous analysis results can be researched, displayed, recalculated, printed or exported via USB interface.

Of course a balance can be connected with the instrument

The VA-51 oven module is available for desorbtion of water, up to 300°C .

Very simple to use, the sample boat is automatically pushed into the transparent oven, where the melting of the sample can be easily monitored.

At the end of the analysis a simple screwed plug give you access to the sample boat.

Maintenance is easy, directly from the front.

The glass titration cell is completely closed and have at the top side some holes (glass-glass connection) accepting the titration electrode and the detection electrode. One can be equipped either with a glass plug or a gas bubbler if you use the VA-51 Oven option.

On the side of the titration cell, your will find an sample injection port, closed with a silicone septa, so it’s easy to inject liquid samples or, by removing the Teflon plug, pour inside the cell your solid sample.

The concept of this cell give the insurance of no leakages or humidity inrush.

As option, our carriage device is used for on site samples analysis, including a separated battery.

Appreciated in industry and refinery, you can make in process analysis in short time, avoiding any contaminations due to transport of the sample at the lab.

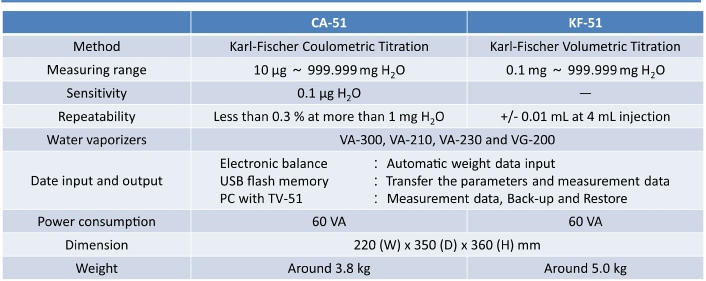

Which instrument configuration fit your need ?

Download info

Download info

Download info

Download info