Are you concerned by AOX /EOX/ CIC or PFAS measurement ?

ALL you need is here ! you are just a phone call away to receive the best quote ever

Call us NOW at +41 24 435 22 02

- 3-injection mode convertible (shaking method/ column method/ EOX)

- Advanced autosampler concept is space saving and reliable

- Faster measurement time

- Automatic gas flow

- No gases required except air (same as AOX-200)

- Longer lifetime of electrolyte by cell cooling system

- Increase the default number of samples

- Easy maintenance of pyrolysis tube by sliding turntable.

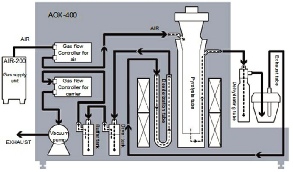

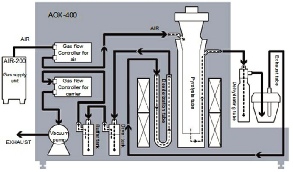

AOX adsorbed on activated carbon is pyrolyzed at high temperature in a quartz combustion tube. Combustion gases containing hydrogen halides are forced through a dehydrating tube and subsequently adsorbed within the electrolyte in a coulometric titration cell.

Within the titration cell the halogen ions are quantified by an argentometric coulometry. The amount of chlorine is calculated from the quantity of electricity required for the formation of silver ions.

HCI + Ag+ ➔ H+ + AgCI (Titration)

Ag ➔ Ag+ + e- (Electrolysis)

The gas is moved by application of suction pump all over the installation, so that no leakage of sample can occur. Using this technology, the residual vapor of acetic acid from the titration cell is destroyed at high temperature into a so called deodorizing tube, placed close to the pyrolysis oven.

Nittoseiko's AOX-400 Automatic Organic Halogen Analyzer measures organic halogen in river water, industrial wastewater, and soil via shaking method, column method, and EOX.

Advanced autosamplers provide flexible combination of different modes easily and in a very small footprint

ISO 9562, DIN EN 1485: Water quality-determination of absorbable organic halogens , AOX/EOX.

EPA 9020, ICR (EPA 814-8-96-002 for QC): Total organic halides , AOX - Column method.

DIN 38414 part 18: Sludge and Sediment-Determination of adsorbed organically bound halogens, AOX -Shaking method

Official method compatibility:

|

Measuring sample

|

River water, Industrial wastewater, Soil

|

|

Sample forms

|

Solid (AOX: activated carbon adsorbed liquid sample), Liquid (EOX: extraction solution)

|

|

Analysis method

|

Oxidative pyrolysis/Coulometry

|

|

Furnace temperature

|

150~ 1000 °C (Regular use: 950° C)

|

|

Sample introduction

|

Introduction to the open top pyrolysis tube type falling drop / AOX: Extrusion injection of activated carbon adsorbed sample (Column method) Drop frit with activated carbon adsorbed sample (Shaking method).

EOX: Direct injection by syringe

|

|

Measurement range

|

Total organic halogen: 0.1 to 50 µ1g

|

|

Sample volume

|

AOX sample: 50mg or less, EOX sample: 200 µL or less

|

|

Measurement time

|

Within 10 minutes/measurement ( 2 µg sample measurement)

|

|

Number of samples

|

Frit: 30 samples

Column: 60 samples

EOX: 40 samples (Size: 2ml vials with septum)

|

|

Gas

|

When using AIR-200 module, air gas is not required.!

AOX: Air (800mL/min)

EOX: Air (l00mL/min) + Oxygen (300mL/min)

|

|

Operation Condition

|

15 to 35 °C, 75%RH or less (no condensation)

|

|

Power supply

|

AC 100/115/230/240V, 50/60Hz, 960VA

|

|

Dimensions & Weight

|

AOX main unit: (W x D x H) : 460 x 420 x 570 mm, 37kg

Sl-400: W x D x H) : 190 x 400 x 410 mm, 7kg

AIR-200: W x D x H) : l00 x 400 x 220 mm, 5kg

|

|

Device control and data processing

|

PC, Printer: compatible with OS W7, 8, 10

|

Ask for info

Ask for info

The activated charcoal columns packed in set of 100 pces and are certified low blank values. The simple, cost-effective and safe solution for your lab. The columns can be used for AOX analysis as well as for AOF determination in combustion-IC and the splitting of AOX into AOCl, AOBr and AOI.

Key Features

– Gas-tight packaging

– 100 columns per pack

– Time and cost saving

– Shelf-stable

– Safe handling

– Easy disposal (waste glass)

– Narrow particle size distribution of the activated carbon

– Quality controlled: Packs with lot number and date.

Standard methods

DIN EN ISO 9562

EN 1485

DIN 38409-H14

DIN 38409-H22

DIN 38409-59

Automated column enrichment module TXA-04

Syringe Disposable syringe 20 ml

Flow method: Automatic syringe system

Maximum Flow Volume:

Syringe for flowing samples: 300 ml (10 × n ml (n=1 to 30))

Syringe for washing: 50 ml (5 × n ml (n=1 to 10))

Syringe quantity 5 pcs (for flowing samples or washing inorganic halide)

Column 3 mm φ x 40 mm, two stage glass column

Power AC 100V to 240V, 50/60Hz, 50VA

Dimensions Approx. 480 (W) x 270 (D) x 530 (H) mm

Weight Approx. 13kg

Ask for info

Ask for info